Грешка у формату е-поште

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

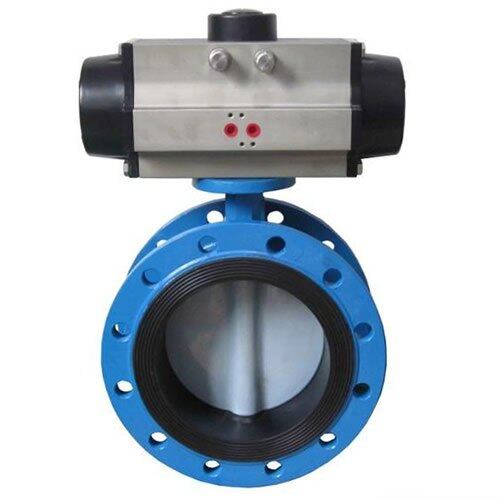

CARBON STEEL BUTTERFLY VALVE

Our carbon steel butterfly valves are widely used in various sectors of the water, oil, and gas industries. They are manufactured using premium grade raw materials to meet global quality standards. We also offer these products at market-leading prices and provide our clients with 24X7 customer service.

Product introduction:

Carbon steel butterfly valve is a valve that uses the unidirectional movement of the butterfly valve as the closing device. Its main structure is composed of two symmetrical motions. The two halves are connected by pivots, so they can be separated by clamping to achieve the purpose of sealing and opening. We offer a wide range of carbon steel butterfly valves that are manufactured, engineered and manufactured by industry standard processes. Our products are famous for their dimensional accuracy, perfect processing and durability. The product is widely used in various sectors of the water, oil and gas industries to prevent fluid backflow.

Carbon steel butterfly valve is a horizontally rotating valve composed of shaft and disc elements. Its main feature is that it can be operated in cylinder type. During operation and movement, there is no leakage and leakage in the medium. The stress is small and stable; With good self closing performance, it can meet the needs of medium temperature, pressure and precision adjustment.

Product advantages:

Our carbon steel butterfly valves are made of high-quality raw materials. Our steel butterfly valves always provide a high performance flow, even at very low differential pressures, available in a variety of sizes and shapes. We provide these products for various industries to meet their various process requirements.

This butterfly valve is made of carbon steel, which has been considered as one of the most widely used materials in the world. Carbon steel has excellent mechanical strength and toughness, and can well resist oxidation, rust or corrosion. It has high ductility, so it can be cold formed when necessary when the metal is in this plastic state. It is still useful at temperatures below freezing. The low carbon content of carbon steel enables it to maintain its mechanical properties at high temperatures.

Carbon steel butterfly valve is a disc valve, in which the valve is controlled by rotating the disc. It belongs to the category of butterfly valve, also known as quarter turn valve, because it has the characteristics of controlling the quarter turn movement of flow. The valve disc usually moves about 10 degrees, but can rotate 180 degrees (6 turns), so it can fully control the flow in one direction and prevent the flow in the opposite direction. Their feature is that there are many precise cuts on the surface of the valve disc, which act simultaneously with the seats on both sides, and make this type of valve have the function of self positioning.

Product design:

The valve is designed to close under normal conditions and open when required. It is designed to control the process by opening and closing as needed. Its simple design, few mechanical components and low cost make it an ideal choice for almost all applications requiring flexible automatic exhaust systems.

Carbon steel butterfly valve is designed to control the flow of liquid and gas in the pipeline. The flat plate of the valve is made of iron, while the bonnet and its internal parts are made of carbon steel. The butterfly valve consists of a disc mounted at the end of the spindle in a cylindrical housing. When the moving disc is moved by appropriate mechanical means, it will open or close an opening in the pipeline. Common applications include gas tanks and other industrial equipment, as well as piping systems for residential heating and cooling systems.

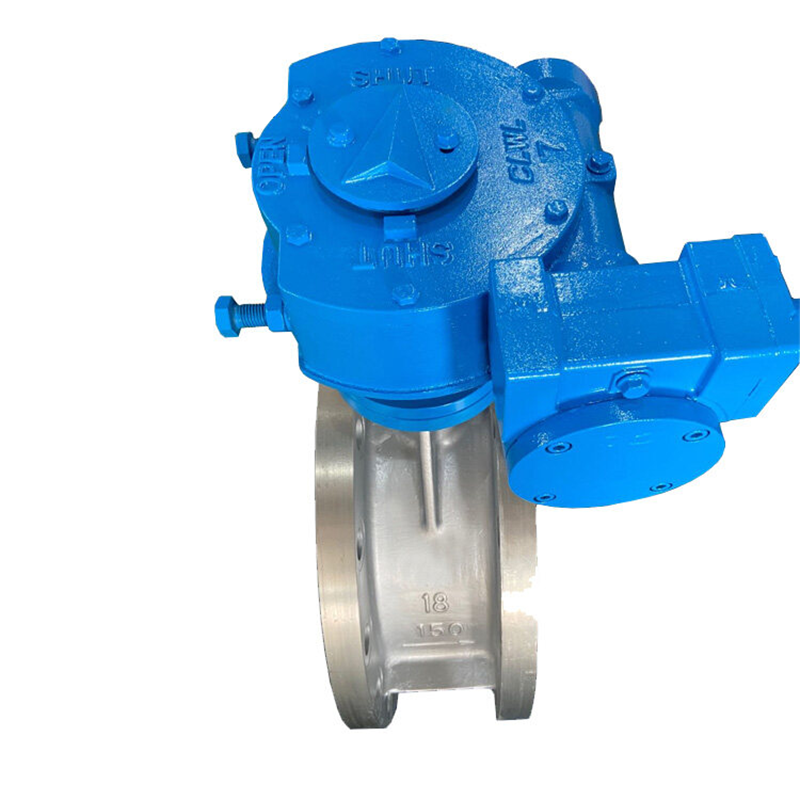

CARBON STEEL BUTTERFLY VALVE

Design standard: API 609.

Body material: GGG40.

Nominal diameter: 28" (DN700).

Pressure: CL150 (PN20).

End connection: RF.

Face to face: ASME B16.10.

Working temperature: -29℃~+130℃.

Mode of operation: Gearbox.

Test and inspection: ANSI

APIRT VALVE Product Range

Body Material: Carbon steel, Stainless steel, Alloy steel.

Normal diameter: 2"~120" (DN50~DN3000).

End connection: Wafer, Lug, Flanged.

Pressure range: 150lbs~600lbs(PN16~PN100).

Operation: Wrench, Gearbox, Electric.

Working temperature: -46℃~+200℃.

Keywords of API 598 Flanged Butterfly Valve, 28 Inch, PN20

Flanged Butterfly Valves, API 598 Butterfly Valve, 28 Inch Butterfly Valve, PN20 Butterfly Valve

Products Related to ANSI Flanged Butterfly Valve, 28 Inch, PN20

TRIPE ECCENTRIC BUTTERFLY VALVE

| TRIPE ECCENTRIC BUTTERFLY VALVEThree-dimensional incline taper airproof seat 900 openinger cleaning Triple eccentric,Bereled wedgedisc small friction and torque,self-clean Manual,electric,pneumatit and gear operation etc. A216WCB,A351 CF8,A351CF8M A217LCB,A351 CF3,A351CF3MTechnical requirements 1.Design and manufacture comply to MSS SP 67-1997 2.Inspect and test comply to API 598 3.Face to face dimetion complies to BSS5155 4.Flanges comply to ANSI 605 5.Pressure-remperature grade complies to ANSI B6.34Material specification |

||||||||||||||||||

| NO. | Part name | Material | ||||||||||||||||

| A216 WCB | A217 LCB | A351 CF8 | A351 CF8M | A351 CF3M | ||||||||||||||

| 1 | Nether cover | A105 | A105 | A182 F304 | A182 F316 | A182 F316L | ||||||||||||

| 2 | Bearing | A182 F6a | A182 F304 | A182 F304 | A182 F316 | A182 F316L | ||||||||||||

| 3 | Wrash | F304+Flexible graphite | ||||||||||||||||

| 4 | Body | A216 WCB | A217 LCB | A351 CF8 | A351 CF8M | A351 CF3M | ||||||||||||

| 5 | Nut | A194 2H | A194 4 | A194 8 | A194 8M | A194 8M | ||||||||||||

| 6 | Bolt | A193 B7 | A193 B16 | A193 B8 | A193 B8M | A193 B8M | ||||||||||||

| 7 | Gland | A182 F410 | A182 F304 | A182 F304 | A182 F316 | A182 F316L | ||||||||||||

| 12 | Key | A194 2H | ||||||||||||||||

| 13 | Gear action | Nodular cast iron | ||||||||||||||||

| 14 | Yoke | A216 WCB | A351 CF8 | |||||||||||||||

| 15 | Shaft packing | Flexible graphite | PTFE | |||||||||||||||

| 16 | Bearing | B148/SF-1/17-7PH | ||||||||||||||||

| 17 | Tailpiece | A216 WCB | A217 LCB | A351 CF8 | A351 CF8M | A351 CF3M | ||||||||||||

| 18 | Seal seat | Flexible graphite | PTFE | |||||||||||||||

| 20 | Pin | A276 316 | A276 316 | A276 316 | A276 316 | A276 316 | ||||||||||||

| 21 | Butterfly board | A351 CF8M | A351 CF8M | A351 CF8M | A351 CF8M | A351 CF3M | ||||||||||||

| 22 | Shaft | A276 316 | A276 316 | A276 316 | A276 316 | A276 316L | ||||||||||||

| 150Lb | ||||||||||||||||||

| NPS | 2~ | 3~ | 4~ | 5~ | 6~ | 8~ | 10~ | 12~ | 14~ | 16~ | 18~ | 20~ | 24~ | 30~ | 32~ | 36~ | 42~ | |

| L-RF | 43 | 64 | 64 | 70 | 76 | 89 | 114 | 114 | 127 | 140 | 152 | 152 | 178 | 229 | 241 | 241 | 305 | |

| L-BW | 107 | 114 | 127 | 140 | 140 | 152 | 165 | 178 | 190 | 216 | 222 | 229 | 267 | 292 | 318 | 330 | 410 | |

| L-WF | 43 | 49 | 56 | 64 | 70 | 71 | 76 | 86 | 92 | 102 | 114 | 127 | 154 | 165 | 190 | 203 | 251 | |

| D1 | 120.5 | 152.5 | 190.5 | 216 | 241.5 | 298.5 | 362 | 432 | 476 | 540 | 578 | 635 | 749.5 | 914 | 978 | 1085 | 1257 | |

| D2 | 92 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 | 857 | 914 | 1022 | 1194 | |

| H | 345 | 380 | 415 | 455 | 545 | 615 | 695 | 830 | 900 | 980 | 1030 | 1110 | 1305 | 1525 | 1585 | 1765 | 1871 | |

| H1 | 280 | 315 | 350 | 390 | 455 | 522 | 605 | 730 | 800 | 870 | 920 | 1000 | 1155 | 1375 | 1435 | 1585 | 1610 | |

| H2 | 110 | 125 | 145 | 165 | 175 | 210 | 250 | 285 | 320 | 355 | 380 | 415 | 475 | 580 | 630 | 680 | 680 | |

| WTKg | RF | 20 | 29 | 35 | 40 | 81 | 94 | 156 | 183 | 239 | 302 | 346 | 434 | 638 | 788 | 880 | 1042 | 1670 |

| BW | 21 | 27 | 34 | 41 | 43 | 81 | 102 | 132 | 164 | 193 | 238 | 302 | 457 | 910 | 1093 | 1410 | 1870 | |

| WF | 9 | 11 | 13 | 16 | 26 | 34 | 51 | 72 | 106 | 133 | 176 | 290 | 394 | 476 | 618 | 762 | 963 | |

| 300Lb | ||||||||||||||||||

| L-RF | 43 | 64 | 64 | 70 | 76 | 89 | 114 | 114 | 127 | 140 | 152 | 152 | 178 | 229 | 241 | 241 | 305 | |

| L-BW | 43 | 49 | 56 | 64 | 70 | 71 | 76 | 86 | 92 | 102 | 114 | 127 | 154 | 165 | 190 | 203 | 251 | |

| L-WF | 160 | 180 | 190 | 200 | 210 | 230 | 250 | 270 | 290 | 310 | 330 | 350 | 390 | 430 | 470 | 510 | 550 | |

| D1 | 127 | 168 | 200 | 235 | 270 | 330 | 387 | 451 | 514 | 571 | 628 | 686 | 813 | 997 | 1054 | 1168 | 1206.5 | |

| D2 | 92 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 | 867 | 914.5 | 1022 | 1136 | |

| H | 345 | 380 | 415 | 455 | 524 | 615 | 695 | 830 | 900 | 980 | 1030 | 1110 | 1305 | 1525 | 1585 | 1765 | 1871 | |

| H1 | 280 | 315 | 350 | 390 | 455 | 525 | 605 | 730 | 800 | 870 | 920 | 1000 | 1156 | 1375 | 1435 | 1585 | 1610 | |

| H2 | 110 | 125 | 145 | 165 | 175 | 210 | 250 | 285 | 320 | 355 | 380 | 415 | 475 | 580 | 630 | 680 | 680 | |

| WTKg | RF | 27 | 31 | 38 | 43 | 45 | 85 | 110 | 142 | 172 | 201 | 245 | 315 | 467 | 922 | 1105 | 1430 | 1890 |

| BW | 24 | 27 | 38 | 50 | 54 | 100 | 13 | 260 | 280 | 320 | 500 | 550 | 900 | 1234 | 1468 | 1782 | 2300 | |

| WF | 11 | 12 | 15 | 18 | 28 | 37 | 56 | 71 | 116 | 146 | 193 | 209 | 433 | 523 | 838 | 972 | 1000 | |